FibreFlex Pro

Description

An innovative Thermoplastic Reinforced Service (TRS) pipe with PE-Xa liner and high modulus aramid reinforcement mesh is used for FibreFlex pipes for a maximum of 10 bar operating pressure and temperature up to 115˚C peak (application temperature profile according to OFI CERT ZG 200-2 Class C).

Both the service pipe and casing have diffusion barrier layers to prevent oxygen entering the system.

Due to reduced wall thickness, FibreFlex Pro service pipes have smaller OD compared to conventional plastic solutions, which allows a thicker insulation layer with same casing dimensions. This, combined with the low value of the cyclopentane-based PUR foam insulation thermal conductivity of 0.021 W/mK, makes FibreFlex Pro pipes an outstanding, highly-energy-efficient solution for heating networks.

FibreFlex Pro is an innovative solution, enables the safe implementation of plastic flexible pre-insulated pipe systems in district heating networks with elevated operating temperatures and pressures, where previously, only steel pipes could be used.

FibreFlex Pro

Description

An innovative Thermoplastic Reinforced Service (TRS) pipe with PE-Xa liner and high modulus aramid reinforcement mesh is used for FibreFlex pipes for a maximum of 10 bar operating pressure and temperature up to 115˚C peak (application temperature profile according to OFI CERT ZG 200-2 Class C).

Both the service pipe and casing have diffusion barrier layers to prevent oxygen entering the system.

Due to reduced wall thickness, FibreFlex Pro service pipes have smaller OD compared to conventional plastic solutions, which allows a thicker insulation layer with same casing dimensions. This, combined with the low value of the cyclopentane-based PUR foam insulation thermal conductivity of 0.021 W/mK, makes FibreFlex Pro pipes an outstanding, highly-energy-efficient solution for heating networks.

FibreFlex Pro is an innovative solution, enables the safe implementation of plastic flexible pre-insulated pipe systems in district heating networks with elevated operating temperatures and pressures, where previously, only steel pipes could be used.

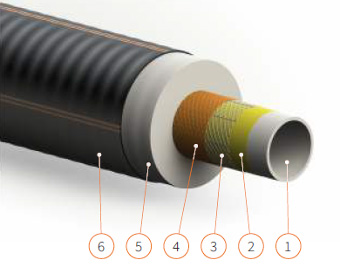

1. PE-Xa service pipe

2. Temperature-resistant adhesive layer

3. High temperature fibre mesh

4. Temperature-resistant adhesive layer including oxygen diffusion barrier

5. Flexible Polyurethane-Foam (PUR)

6. Service pipe outer layer

Information

Max. peak operating temperature

+115°C

Thermal conductivity

0.021 W/mK

Operating pressure

10 bar

Service pipe

PE-Xa with aramid reinforcement

Thermal conductivity

PUR, CFC-free cyclopentane-based

Service pipe

Corrugated PE-LD

Accessories

FibreFlex / FibreFlex Pro press fittings have an additional polymer crimp sleeve between the sliding sleeve and the service pipe. As a result, the support bushing can be inserted directly into the pipe ends during installation without widening. Up to size 110, standard pressing tools such as for PE-Xa pipes (SDR11) can be used. The Radius-Kelit pressing tool is available for larger dimensions. The pressing point is insulated with joint system.

FibreFlex Installation – Radius-Kelit

Installation of a FibreFlex Pro Press Coupler + Sleeve Heat Shrink Insulation.

Accessories

FibreFlex / FibreFlex Pro press fittings have an additional polymer crimp sleeve between the sliding sleeve and the service pipe. As a result, the support bushing can be inserted directly into the pipe ends during installation without widening. Up to size 110, standard pressing tools such as for PE-Xa pipes (SDR11) can be used. The Radius-Kelit pressing tool is available for larger dimensions. The pressing point is insulated with joint system.

FibreFlex Installation – Radius-Kelit

Installation of a FibreFlex Pro Press Coupler + Sleeve Heat Shrink Insulation.

Advantages

Fiber Flex the ideal solution for :

- No risk of corrosion to piping, internal or external

- Significantly reduced jointing due to linear coils over 80 m, minimizing system weaknesses

- Improved flow rates with less resistant plastic piping that reduces pumping requirements and energy efficiency

- Guaranteed design life >50 years

- Advantages of heat loss over traditional steel systems

- No leak detection measures required capital cost savings and removal of the unreliable detection system with annual maintenance costs

- Minimized expansion and contraction

- Local district heating networks

- Low-temperature city heat networks

- High pressure heating systems in hilly areas

- Agricultural applications

- Private domestic heating applications

- Other heated fluid pipeline applications with system operating temperatures and pressures up to +95°C and 10 bar.

Advantages

- No risk of corrosion to piping, internal or external

- Significantly reduced jointing due to linear coils over 80 m, minimizing system weaknesses

- Improved flow rates with less resistant plastic piping that reduces pumping requirements and energy efficiency

- Guaranteed design life >50 years

- Advantages of heat loss over traditional steel systems

- No leak detection measures required capital cost savings and removal of the unreliable detection system with annual maintenance costs

- Minimized expansion and contraction

Fiber Flex the ideal solution for :

- Local district heating networks

- Low-temperature city heat networks

- High pressure heating systems in hilly areas

- Agricultural applications

- Private domestic heating applications

- Other heated fluid pipeline applications with system operating temperatures and pressures up to +95°C and 10 bar.

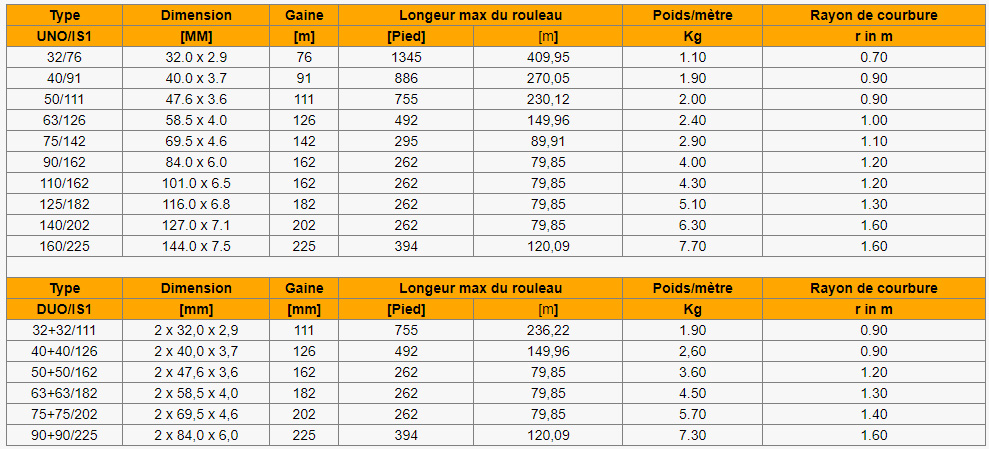

Pipe product range