Fibre Flex

Description

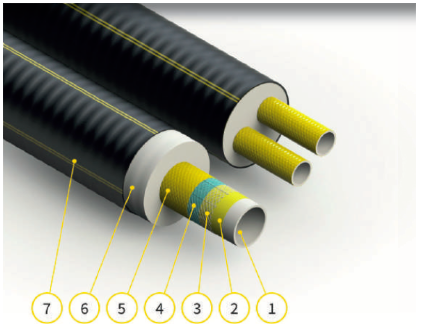

An innovative Thermoplastic Reinforced Service (TRS) pipe with PEX-a liner and a high modulus aramid reinforcement mesh is used for FibreFlex pipes for maximum 10 bar operating pressure at continuous 80˚C operating temperature (application temperature profile according to EN 15632-2, OFI CERT ZG 200-2 Class A). An oxygen barrier layer prevents oxygen diffusion into the network.

Due to reduced wall thickness, FibreFlex service pipes have smaller OD compared to conventional plastic solutions, which allows a thicker insulation layer with same casing dimensions. This, combined with the low thermal conductivity value of the cyclopentane-based PUR foam insulation 0.021 W/mK, makes FibreFlex pipes an outstanding, highly-energy-efficient solution for heating networks. Use of FibreFlex pipes in applications with operating pressures lower than 10 bar provides a higher safety factor for heating pipe networks. The FibreFlex pipe system is manufactured in accordance with OFI CERT ZG 200-2 Class A Technical Specification.

Fibre Flex

Description

An innovative Thermoplastic Reinforced Service (TRS) pipe with PEX-a liner and a high modulus aramid reinforcement mesh is used for FibreFlex pipes for maximum 10 bar operating pressure at continuous 80˚C operating temperature (application temperature profile according to EN 15632-2, OFI CERT ZG 200-2 Class A). An oxygen barrier layer prevents oxygen diffusion into the network.

Due to reduced wall thickness, FibreFlex service pipes have smaller OD compared to conventional plastic solutions, which allows a thicker insulation layer with same casing dimensions. This, combined with the low thermal conductivity value of the cyclopentane-based PUR foam insulation 0.021 W/mK, makes FibreFlex pipes an outstanding, highly-energy-efficient solution for heating networks. Use of FibreFlex pipes in applications with operating pressures lower than 10 bar provides a higher safety factor for heating pipe networks. The FibreFlex pipe system is manufactured in accordance with OFI CERT ZG 200-2 Class A Technical Specification.

1. PE-Xa service pipe

2. Adhesive layer

3. Aramid fibre mesh

4. Adhesive layer including oxygen diffusion barrier

5. Service pipe outer layer

6. Flexible Polyurethane-Foam (PUR)

7. Casing

Information

Max. continuos operating temperature (acc. to EN15632)

+80°C

Max. operating temperature

+95˚C (Variable*)

Thermal conductivity

0.021 W/mK

Operating pressure

10 bar

Accessories

FibreFlex / FibreFlex Pro press fittings have an additional polymer crimp sleeve between the sliding sleeve and the service pipe. As a result, the support bushing can be inserted directly into the pipe ends during installation without widening. Up to size 110, standard pressing tools such as for PE-Xa pipes (SDR11) can be used. The Radius-Kelit pressing tool is available for larger dimensions. The pressing point is insulated with joint system.

FibreFlex Installation – Radius-Kelit

Installation of a FibreFlex Pro press coupler and heat shrink sleeve insulation.

Accessories

FibreFlex / FibreFlex Pro press fittings have an additional polymer crimp sleeve between the sliding sleeve and the service pipe. As a result, the support bushing can be inserted directly into the pipe ends during installation without widening. Up to size 110, standard pressing tools such as for PE-Xa pipes (SDR11) can be used. The Radius-Kelit pressing tool is available for larger dimensions. The pressing point is insulated with joint system.

FibreFlex Installation – Radius-Kelit

Installation of a FibreFlex Pro press coupler and heat shrink sleeve insulation.

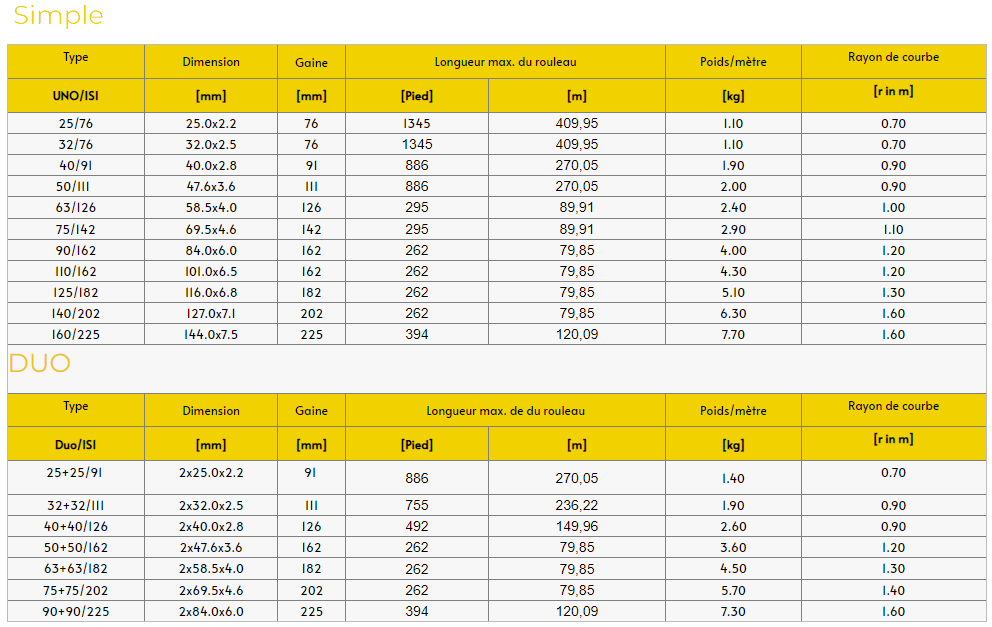

Product range pipe